설명

210x190x200 1,300.00 Kg환경 설정

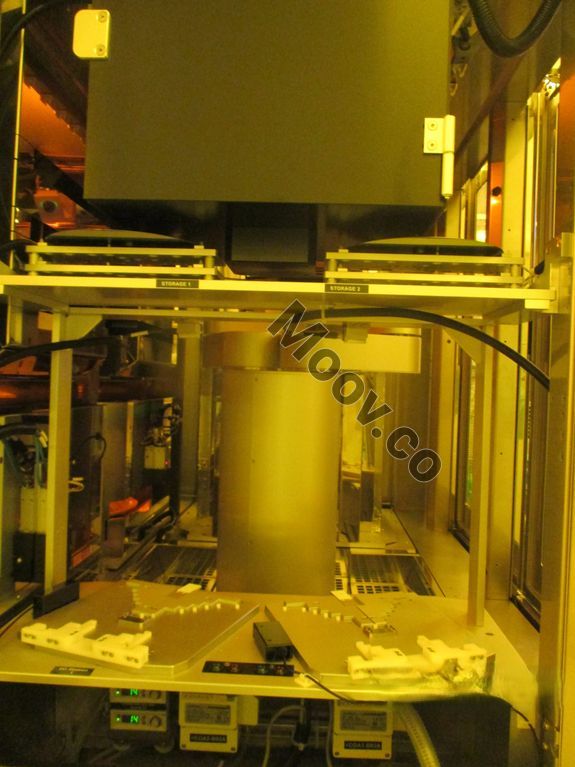

Power Supply: 3 phase, 380 V, 7 A, 60 Hz Heaters: 7 heaters HDMS: (Not explicitly stated – needs confirmation) Resists: 2 resists The machine has two chambers. Whether it can perform development depends on the chemical process. Since this machine currently uses PR photoresist, it only has coating functionality. If used for PI processes, it can perform both coating and development simultaneously. Coaters / Coolers: 2 coater modules. The machine had 3 cool plates and 8 storage in the machine. Tanks: Uses 4 different tanks; equipped with more than 6 flow meters (top side/back side / pre-wet / EBR / cover flow) Wafer Size: Processes 8-inch wafers onlyOEM 모델 설명

The SUSS ACS200 Gen3 platform is the successful result of a perfect mix of innovative and production proven components. With the capability of up to 4 wet process modules and a maximum of 19 plates it perfectly suits the needs of high volume manufacturing (HVM). The unmatched configuration flexibility of modules and technologies covers not only the requirements of the Advanced Packaging, MEMS and LED market it also bridges the gap between R&D and HVM.문서

문서 없음

카테고리

Coaters & Developers

마지막 검증일: 어제

주요 품목 세부 정보

조건:

Used

작동 상태:

Installed / Running

제품 ID:

136190

웨이퍼 사이즈:

8"/200mm

빈티지:

2018

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

유사 등재물

모두 보기SUSS MicroTec / KARL SUSS

ACS200 Gen3

카테고리

Coaters & Developers

마지막 검증일: 어제

주요 품목 세부 정보

조건:

Used

작동 상태:

Installed / Running

제품 ID:

136190

웨이퍼 사이즈:

8"/200mm

빈티지:

2018

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

설명

210x190x200 1,300.00 Kg환경 설정

Power Supply: 3 phase, 380 V, 7 A, 60 Hz Heaters: 7 heaters HDMS: (Not explicitly stated – needs confirmation) Resists: 2 resists The machine has two chambers. Whether it can perform development depends on the chemical process. Since this machine currently uses PR photoresist, it only has coating functionality. If used for PI processes, it can perform both coating and development simultaneously. Coaters / Coolers: 2 coater modules. The machine had 3 cool plates and 8 storage in the machine. Tanks: Uses 4 different tanks; equipped with more than 6 flow meters (top side/back side / pre-wet / EBR / cover flow) Wafer Size: Processes 8-inch wafers onlyOEM 모델 설명

The SUSS ACS200 Gen3 platform is the successful result of a perfect mix of innovative and production proven components. With the capability of up to 4 wet process modules and a maximum of 19 plates it perfectly suits the needs of high volume manufacturing (HVM). The unmatched configuration flexibility of modules and technologies covers not only the requirements of the Advanced Packaging, MEMS and LED market it also bridges the gap between R&D and HVM.문서

문서 없음