설명

설명 없음환경 설정

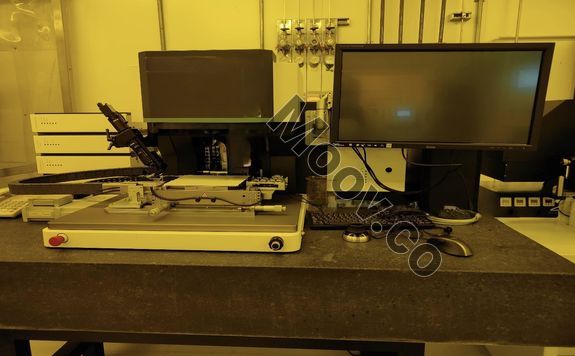

- Base systems & accessories: Fineplacer Sigma Flip-Chip bonder, low force version (0.2-40N, resolution 0.1N for forces up to 1% of set value for forces above 10N), base system for pick & place without application modules and tooling. Adjustment set 0.5 um. For verification of placement accuracy and adjustment in X-Y-Theta. - Positioning tables & options: Motorized Z-travel for; positioning table. Software-controlled Z-travel integrated in the position table. For high-precision and software controlled adjustment of Z level with 1 um resolution. Universal Tray support. Supports up to four 2' packs or one 4' pack, e.g. waffle packs, GelPak - Placement arms/unheated heads & accessories: Tooltip changing option. Using a special routine, the tooltip surface can be set exactly parallel to the landing surface and is therefore ideal for applications with the highest demands on parallelism in the assembly process. Changeable tool tip, special. Component specific tips to be used with tool-tip changer module. Please make a statement on your component specifications / data sheet during order. - Heating Modules & Accessories: Fast Chip Heating Module 300 W (w/o tool). Max. setting temperature 450°C, ramps 1-20 K/s for heating. Controlled cooling via compressed air or nitrogen. For chip sizes up to approx. 30 mm x 30mm. Tootip-support incl. 300W heater. For holding heatable tool tips. The heat is applied by direct contact to the component. Substrate heating module 50mm x 50mm. Ceramics heater 1700 W. Max. setting temp 450 °C, stand-by temp 40-250°C, 1 K/min - 25 K/s for heating. Hybrid cooling up to 10 K/s and liquid cooling for thermal stabilization. Substrate support with standard vacuum structure (cross -shaped, 4 mm x4 mm, center of plate.) Controlled with IPM software. For bonding forces up to 500 N. Process gas enclosure for FA7, FA15, FA17 and FA9. For bonding processes under gas atmosphere with N2, Ar and H2N2. Gas switching through the heating plate control box. Flow rate control via software. - Bonding force modules and options: Bonding force module automatic, 500 N, surcharge. - resolution 1: 0.2 N for forces up to 40 N - resoltuion 2: 1% of the rated value for forces higher than 40 N - Video modules & options: Process video module. For in-situ process observation using USB camera. Automatic switching between alignment camera and process camera when the placement are moves up/down.OEM 모델 설명

Die Bonder문서

문서 없음

카테고리

Die Bonders / Sorters / Attachers

마지막 검증일: 30일 이상 전

주요 품목 세부 정보

조건:

Used

작동 상태:

알 수 없음

제품 ID:

137374

웨이퍼 사이즈:

알 수 없음

빈티지:

2023

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

FINETECH INC

FINEPLACER sigma

카테고리

Die Bonders / Sorters / Attachers

마지막 검증일: 30일 이상 전

주요 품목 세부 정보

조건:

Used

작동 상태:

알 수 없음

제품 ID:

137374

웨이퍼 사이즈:

알 수 없음

빈티지:

2023

Logistics Support

Available

Transaction Insured by Moov

Available

Refurbishment Services

Available

설명

설명 없음환경 설정

- Base systems & accessories: Fineplacer Sigma Flip-Chip bonder, low force version (0.2-40N, resolution 0.1N for forces up to 1% of set value for forces above 10N), base system for pick & place without application modules and tooling. Adjustment set 0.5 um. For verification of placement accuracy and adjustment in X-Y-Theta. - Positioning tables & options: Motorized Z-travel for; positioning table. Software-controlled Z-travel integrated in the position table. For high-precision and software controlled adjustment of Z level with 1 um resolution. Universal Tray support. Supports up to four 2' packs or one 4' pack, e.g. waffle packs, GelPak - Placement arms/unheated heads & accessories: Tooltip changing option. Using a special routine, the tooltip surface can be set exactly parallel to the landing surface and is therefore ideal for applications with the highest demands on parallelism in the assembly process. Changeable tool tip, special. Component specific tips to be used with tool-tip changer module. Please make a statement on your component specifications / data sheet during order. - Heating Modules & Accessories: Fast Chip Heating Module 300 W (w/o tool). Max. setting temperature 450°C, ramps 1-20 K/s for heating. Controlled cooling via compressed air or nitrogen. For chip sizes up to approx. 30 mm x 30mm. Tootip-support incl. 300W heater. For holding heatable tool tips. The heat is applied by direct contact to the component. Substrate heating module 50mm x 50mm. Ceramics heater 1700 W. Max. setting temp 450 °C, stand-by temp 40-250°C, 1 K/min - 25 K/s for heating. Hybrid cooling up to 10 K/s and liquid cooling for thermal stabilization. Substrate support with standard vacuum structure (cross -shaped, 4 mm x4 mm, center of plate.) Controlled with IPM software. For bonding forces up to 500 N. Process gas enclosure for FA7, FA15, FA17 and FA9. For bonding processes under gas atmosphere with N2, Ar and H2N2. Gas switching through the heating plate control box. Flow rate control via software. - Bonding force modules and options: Bonding force module automatic, 500 N, surcharge. - resolution 1: 0.2 N for forces up to 40 N - resoltuion 2: 1% of the rated value for forces higher than 40 N - Video modules & options: Process video module. For in-situ process observation using USB camera. Automatic switching between alignment camera and process camera when the placement are moves up/down.OEM 모델 설명

Die Bonder문서

문서 없음